Workplace Inspection Guideline and Procedure

Workplace Inspections

Workplace Inspections are carried out to ensure all work areas are kept free from hazards or potential hazards that may lead to injury, illness, near miss, property damage or adverse environmental impact.

Managers are required to conduct workplace inspections in all University workplaces occupied by their staff, students or contractors in consultation with the local Health and Safety Representative (if there is one). Booked spaces such as meeting rooms or lecture theatres are the responsibility of the FIOA that manages the bookings (in many cases Facilities Services Division).

What is an inspection?

An inspection is an examination of the workplace to check for hazards and operational safety standards are being maintained. An inspection might involve an informal, unscheduled walk around the site, or a formal, planned inspection.

An inspection:

- assesses the safety of current activities or equipment

- looks for health and safety improvement opportunities

- identifies immediate or potential hazards

- provides positive feedback on good safety practices

- provides an opportunity to listen to the concerns of staff and team leaders

- provides an effective way to follow-up on improvements or hazard control measures

- allows the closure of outstanding corrective actions

- demonstrates that management is serious about improving safety for all workers

- provides evidence of compliance with OHS legislation.

An inspection may target the entire workplace, a particular area of operations or even a single piece of equipment.

Regular scheduled inspections must be carried out by a team including line management (e.g. a supervisor or local manager) and the HSR (where elected). They should use checklists that have been tailored to the particular area and its operations.

Most office-based inspections focus on housekeeping. However consider whether the inspection should include the following:

- Safety and wellbeing information: Consider whether appropriate information in the form of posters, signs, manuals are provided

- Plant and equipment: Examine all plant and equipment operating at the site

- Machine guarding: Check to ensure that guards and barriers are in place at risk points on machinery to prevent injury from blades on saws, nip points in machinery, or other crush or entanglement risks.

- Materials: Check whether materials, including chemicals, used or stored in the workplace could pose a health and safety risk,

- Work practices: Observe how workers are working, including manual handling and lifting.

- Housekeeping: Examine how the work site is maintained. Check for rubbish stored in front of exit doors, extension cords that present trip or electrocution risks, slip hazards caused by waste or substances on walks areas, etc.

- Use of PPE: Make sure workers, visitors and other people attending the site are wearing appropriate PPE.

- Mobile plant and pedestrian interfaces: Assess the safety of areas that people and vehicles share.

- Emergency arrangements: Examine the processes and procedures in place to protect the safety of workers in the event of an emergency such as fire, a chemical spill or other unexpected event that places workers at risk.

- Building: Examine the building and the land it sits on for hazards, such as: protruding structures, loading ramps, doors opening onto traffic, areas that require ventilation or air monitoring.

- Structures: Assess the condition of internal and external structures on the site, e.g. fences, rails, walkways, walls, hoardings etc. In particular look for signs of damage or deterioration that could lead to accidents or even collapse.

A record should be kept of who carried out the inspection, the date, locations inspection, a short overall comment and any issues that need to be followed up.

Inspection Compliance Procedure

| Methodology | Resources / Tools / Further Information |

| Step 1: The Head of the FIOA develops an inspection schedule for the year and documents it in the HWS Activity Plan. | |

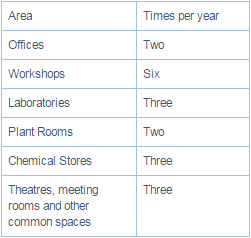

| Step 2: The frequency of the inspections is determined by the adjacent schedule unless varied otherwise by risk assessment. |

|

Step 3: The inspection team must include the local manager or supervisor. Where there is an elected employee health and safety representative (HSR), that person must be given the opportunity to be involved. Other workers in the area being inspected may also be involved. |

|

| Step 4: The local manager will use, develop or adapt an appropriate checklist. | |

| Step 5: The team uses the checklist as a prompt during the inspection and to document any findings. |

|

| Step 6: The local manager must keep a record of the inspection including date, participants and location(s). A simple corrective action plan should be drawn up for issues that could not be resolved immediately. |

|

Step 7: The manager/supervisor must:

|

|

| Step 8: Where the person responsible for the corrective action is not the local manager/supervisor, the responsible person must determine the nature and the time frame of the corrective action. | |

| Step 9: The responsibility for following up and monitoring corrective actions remains with the local manager even though the responsibility for completing individual items may lie elsewhere. |

|

| Step 12: The local manager must keep inspection reports and Action Plans for a minimum of 5 years and, where requested, provide them to OHS Representatives and auditors. | |

| The following two steps are optional and depend upon local arrangements. | |

Step 10: After the inspection and development of any Action Plan, the following the local manager must report to the Head of the FIOA:

| |

Step 11: The Head of the FIOA as part of their annual HWS Plan report will include the following:

| |