Can organic waste from industry be turned into new products? A new Deakin REACH partnership will explore what's possible.

Research news

Summary:

- Australia is one of the highest waste generators in the world, with over 7.6 million tonnes of food ending up in landfill each year, costing over $36.6 billion and producing 17.5 million tonnes of greenhouse gas.

- Deakin’s partnership with Jet Technology through REACH will explore ways to transform industry-generated organic waste into new products like organic textiles and stock feed using a rapid composting system.

- Jet Technology’s Environmental Recycling System (ERS) will build a circular economy by creating valuable products for a range of industry sectors.

Australia is continuing to generate more landfill each year. A new partnership between Deakin’s Recycling and Clean Energy Commercialisation Hub (REACH) and Japanese-based company Jet Technology aims to turn this around by repurposing organic waste and transforming it into new products.

Australia contributes more than 7.6 million tonnes of food to landfill annually, costing over $36.6 billion and producing 17.5 million tonnes of CO2.

Deakin University scientist Alfred Deakin Professor and Chair in Biotechnology Colin Barrow and his team from the Centre for Sustainable Bioproducts will work with Jet Technology to explore the possible reuses of organic waste using Jet Technology’s Environmental Recycling System (ERS). The project will focus on converting organic waste from the agriculture, dairy and fishery sectors by drastically shortening composting time so it can be used to make new products.

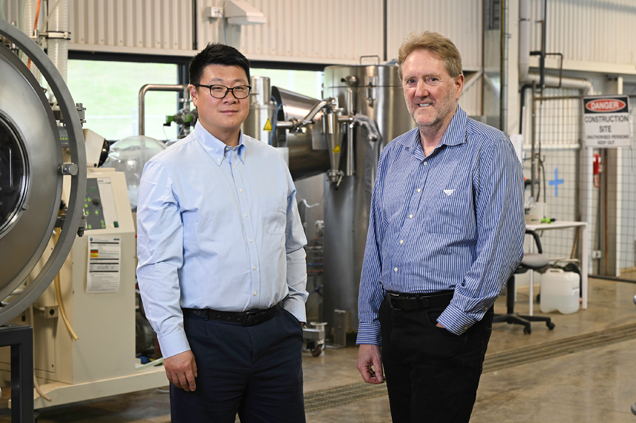

CEO of Jet Technology Howard Ju with Alfred Deakin Professor and Deakin Chair in Biotechnology Colin Barrow.

Jet Technology’s CEO Howard Ju says Australia is rich in agricultural and fishery resources, and these resources represent significant tonnage of organic product to be scaled-up for commercialisation.

“Through this pilot project we will develop a range of applications and solutions to resolve current organic waste issues for different sectors and improve Australia’s organic resource recovery,” he explains.

“Our world leading ERS technology significantly reduces the organic recycling process from weeks or months to a few hours. It is a clean process with almost zero pollution to the environment that will produce organic products, such as fertiliser, cow feed and textiles.”

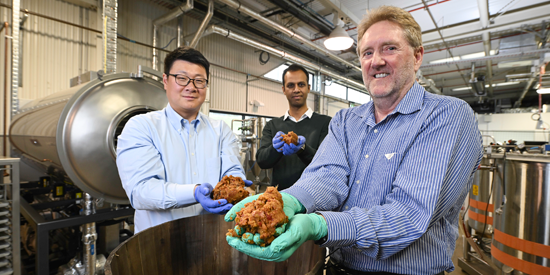

The four-year research project will be undertaken at the BioFactory at Deakin’s Waurn Ponds campus. It will initially focus on processing agricultural waste, converting apple pomace into a bioproduct for the textile industry. Apple pomace consists of the apple skin, pulp, seeds and stems left over from apple juice manufacturing. Its disposal in landfill can lead to greenhouse gas emissions and potential contamination of soil and groundwater.

Raw apple pomace ready for reuse.

The project will also look at new ways to deal with one of Australia’s biggest organic waste problems. Bagasse, the material left over when sugar is made, accounts for around 20% of the nation’s organic waste. The researchers will investigate ways that Australia’s 10 million tonnes of bagasse can be reused as a food source for cows that has the potential to yield $1000 per tonne commercially.

Professor Barrow said sending organic waste to landfill is a missed opportunity to use it as a resource.

“Through this project we are exploring innovative methods to reduce organic waste, mitigate environmental impacts, and create value-adding products for a range of sectors,” he says.

“Supporting Jet Technology with supply chains and infrastructure, we will develop viable solutions for repurposing industry-generated organic waste to build a circular economy across different sectors, unlocking millions of dollars in value and strengthening domestic manufacturing.”

If successful, it could lead to the establishment of a local multi-million-dollar bioeconomy where organisations such as councils, supermarkets and food and beverage businesses could cut costs while generating new revenue streams and job opportunities.

Deakin’s REACH initiative collaborates with progressive industry, government, and education partners to establish a multi-billion-dollar bioeconomy in Victoria and push the limits of technological innovation to deliver energy and recycling solutions that reduce landfill, fossil fuel emissions, and the devastating costs of global warming.

To share your greener supply chains with Deakin and accelerate the move to a circular economy, contact us at reach@deakin.edu.au.

Share this story

Key Fact

(L-R) Howard Ju, CEO of Jet Technology; School of Life and Environmental Sciences Research Fellow Motilal Mathesh; and Alfred Deakin Professor and Deakin Chair in Biotechnology Colin Barrow. They're working on a REACH industry partnership project to turn apple waste into new products like organic textiles.