The Structural engineering lab is equipped with a range of high-precision technology to help you develop and visualise complex engineering principles and design.

Material and large-scale structural testing

In addition to a suite of imaging devices to help track test data, we’ve got a selection of National Association of Testing Authorities (NATA) certified load frames of varying kN capacity for testing bend and compression limits. Plus, material testing equipment for determining the characteristics of various materials, such as:

- porosity

- corrosion resistance

- x-ray diffraction

- penetration resistance

- moisture

- internal pH,

- carbonation,

- sulphate resistance,

- petrographic analysis,

- alkali aggregate reactivity and sorptivity.

Non-destructive evaluation of structure and structural dynamics

Throughout your degree you’ll learn how to harness non-destructive structural testing equipment, using oscillation waves and vibrations to test structural integrity using machines such as:

- NI PXIe-8135 guided wave embedded controllers

- NI PXIe-5105 Oscilloscopes

- NI PXI-5412 Arbitrary waveform generators

- Ultrasonic pre-amplifiers

- Contact transducers

- NI cDAQ-9133 Compact Data Acquisition Systems

- Vibration input modulus NI-9232

- Uni-, bi- and tri-axial accelerometers

- Modal hammers

- Piezocomposite actuators.

You’ll also get to experiment with our wind tunnel testing facilities.

Durability and simulated environment

The lab contains an environmental chamber, used to control moisture, temperature and UV light. Throughout your study, you’ll use this chamber to create simulated environments to put materials to the test through wet-dry cycles and accelerated aging experiments.

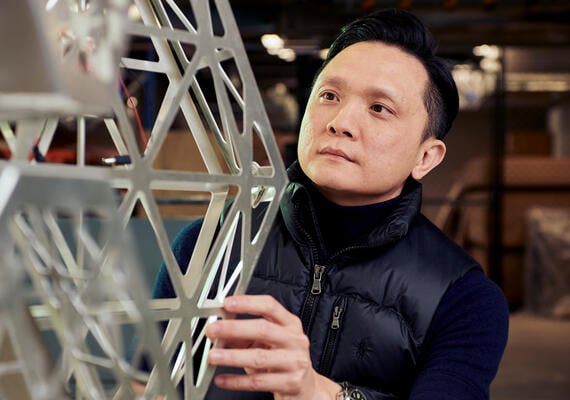

Mechanical workshop

In additional to our testing facilities, the lab is also equipped with fabrication equipment. You’ll have the opportunity to make use of both general-purpose workstations and hand tools, as well as complex machinery such as lathes, laser cutters, water jet cutters and 3D printers.